GIS components handle pressure, filtration, heating and degassing with integrated control and operator interface. Modular building blocks support aqueous, UV-curable and functional fluids, subject to materials compatibility.

Header tanks & system controls

Maintaining stable flow

GIS provide standalone electronics and software to regulate meniscus pressure, maintain stable flow and manage recirculation where required. Header tanks and control modules scale from lab rigs to multi-head bars. Proven control logic reduces failure modes such as poor pressure control or sedimentation.

The GIS Ink System Components can be used with almost all industrial inkjet printheads and the majority of ink types including aqueous, UV curable and functional fluids – subject to materials compatibility tests.

GIS Software and Electronics for IDS

Configured to your specific requirements

We work with customers to design and configure a system tailored to your specific requirements. We design custom parts if required and we adopt a “building block” approach allowing machine builders ultimately to source their own components such as ink pumps and filters, which reduces their costs.

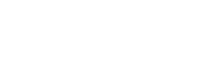

Each Ethernet networked GIS ink control board (ISC-IMB-I6) can control from 1 to 6 fluids/inks independently. Two or more boards can be connected for systems that require 7 – 12 fluids/inks and beyond.

Header tanks

Full range of standard header tank designs

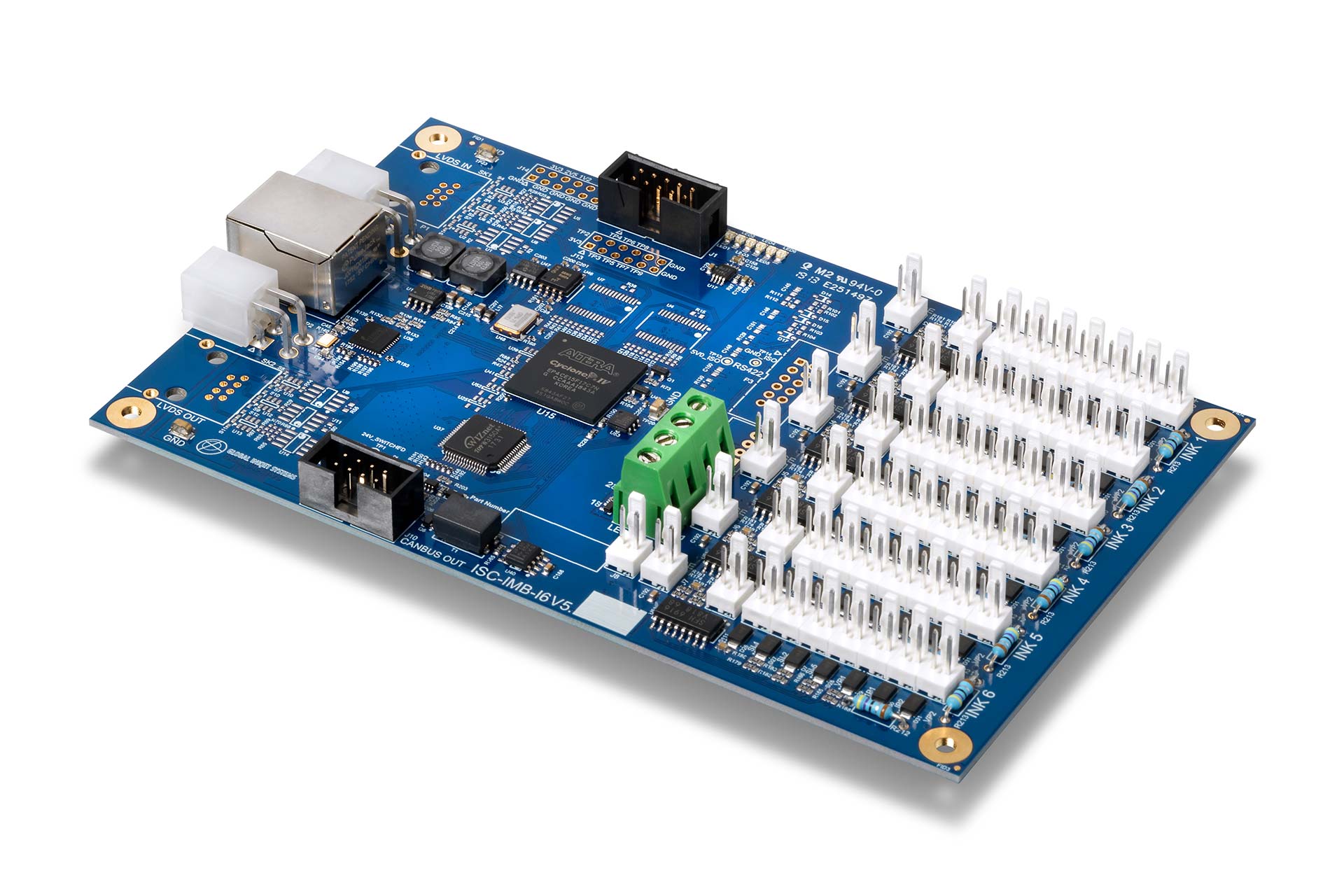

A full range of standard tanks is sized to the number of printheads per colour for correct volume and flow. Each tank includes overflow protection, pressure sensor(s) for accurate meniscus control and alarms, and integral control valves to switch modes with automatic shut-off.

Manual isolation valves per head enable quick head replacement and long-term shut-down. Swagelok stainless-steel connectors to the printhead and Luer-lok connectors for ink in/out provide secure joints and fast servicing. Internal flow paths minimise pigment traps and promote air release for consistent drop formation.

Purge control

For high and low pressure systems

The module supports high and low-pressure purge with manual long-term shut-off. Printheads can be changed without draining. Fault detection monitors operation and raises clear alerts. Heating is available in-line and at the header tank, with an ink degasser to improve stability and drop formation.

Control cards daisy-chain to add colours. A single-cable CAN bus links to one header tank per colour, and header tanks can be daisy-chained. The system runs from a 24 V supply and connects to a PC over Ethernet.

Next step…

Connect with us

We’d love to hear from you

If you are building a new machine or re-engineering a platform, talk to the GIS team. Want a more in-depth plan, or just a sanity check? Get in touch. We can set up a technical review through the form or take your call for a quick question.